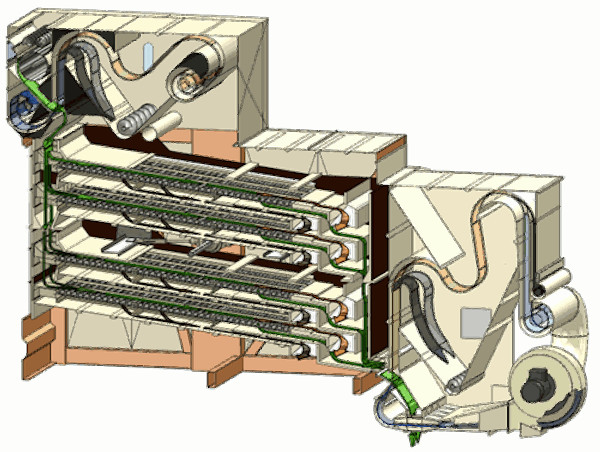

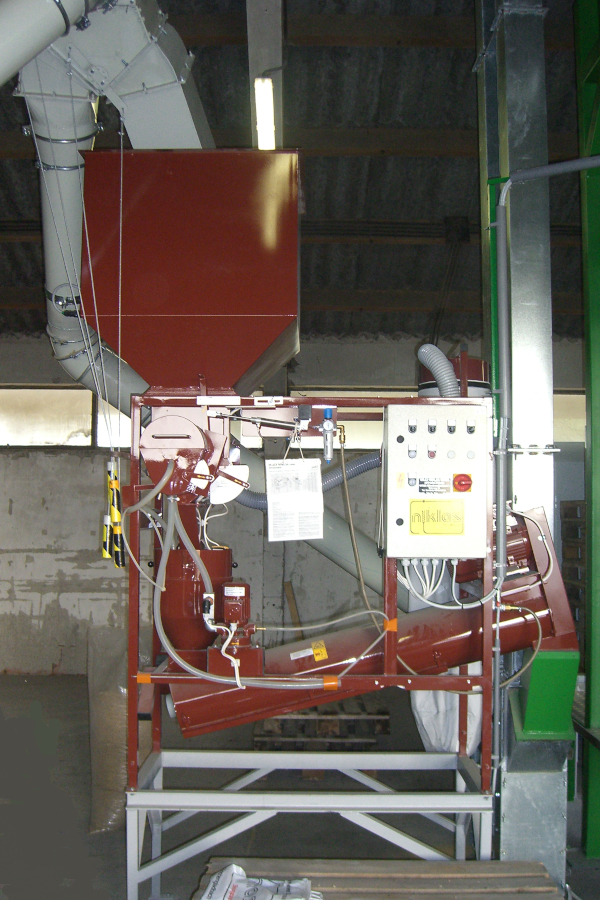

The PULCO ascending sifter performs an effective air sorting job, both with light and heavy seeds. The ascending sifter can be easily installed in almost any plant – ideally suited for dust-free loading!

For example. for pre-cleaning on reception, for additional air cleaning in a fine cleaning process, for perfect seed preparation before dressing, for optimum quality sorting and many more applications. The PULCO is designed to provide the best possible cleaning under all circumstances. It can also be used for fractionation using a coarse separator.

The PULCO is a simple, environmentally friendly construction, is easy to operate and can be equipped with a remote control.

Advantages:

- self-draining and perfect flow of air due to the ideal distribution of the material

- vibration-free and space-saving in relation to its excellent performance

- low-noise, energy- and environmentally friendly

- modular accessories program for present and future needs

- no screen wear

- low drive power with high work output

You can download details here