Alvan Blanch universal dryer

If you are looking for an efficient, continuous dryer that can process any material (fermentation residues, woodchip, grain, paper sludge, waste, etc), then the Alvan Blanch universal dryers are the right choice!

Alvan Blanch – Unique. Versatile. Flexible.

Technical details:

If you are looking for an efficient, continuous dryer that can process any material (fermentation residues, woodchip, grain, paper sludge, waste, etc), then the Alvan Blanch universal dryers are the right choice!

Alvan Blanch – Unique. Versatile. Flexible.

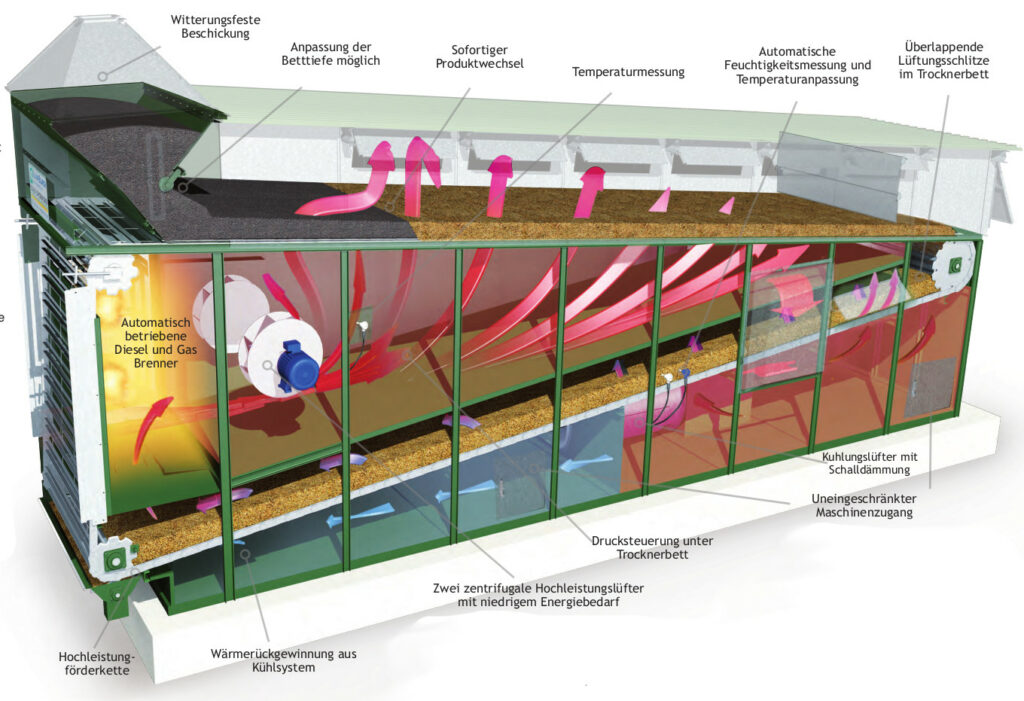

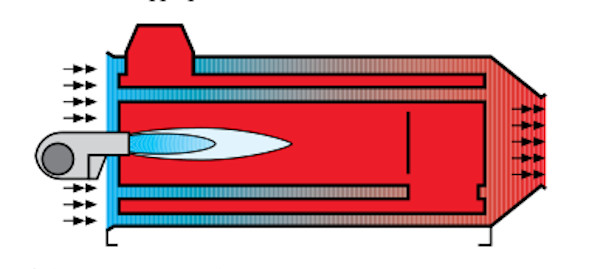

Picture photo brochure conveyor belt dryer

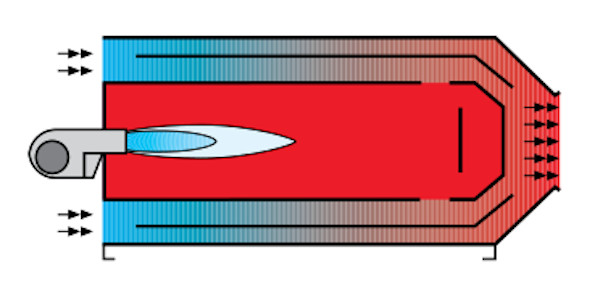

Multiple heat sources

Various heat sources can be used, such as waste heat from biogas plants, liquid gas, natural gas or oil burners (direct/indirect), hot water, steam and much more.

Due to a large drying area and low-temperature drying, it is ideally suited for temperature-sensitive products such as hemp, lucerne, beans etc.

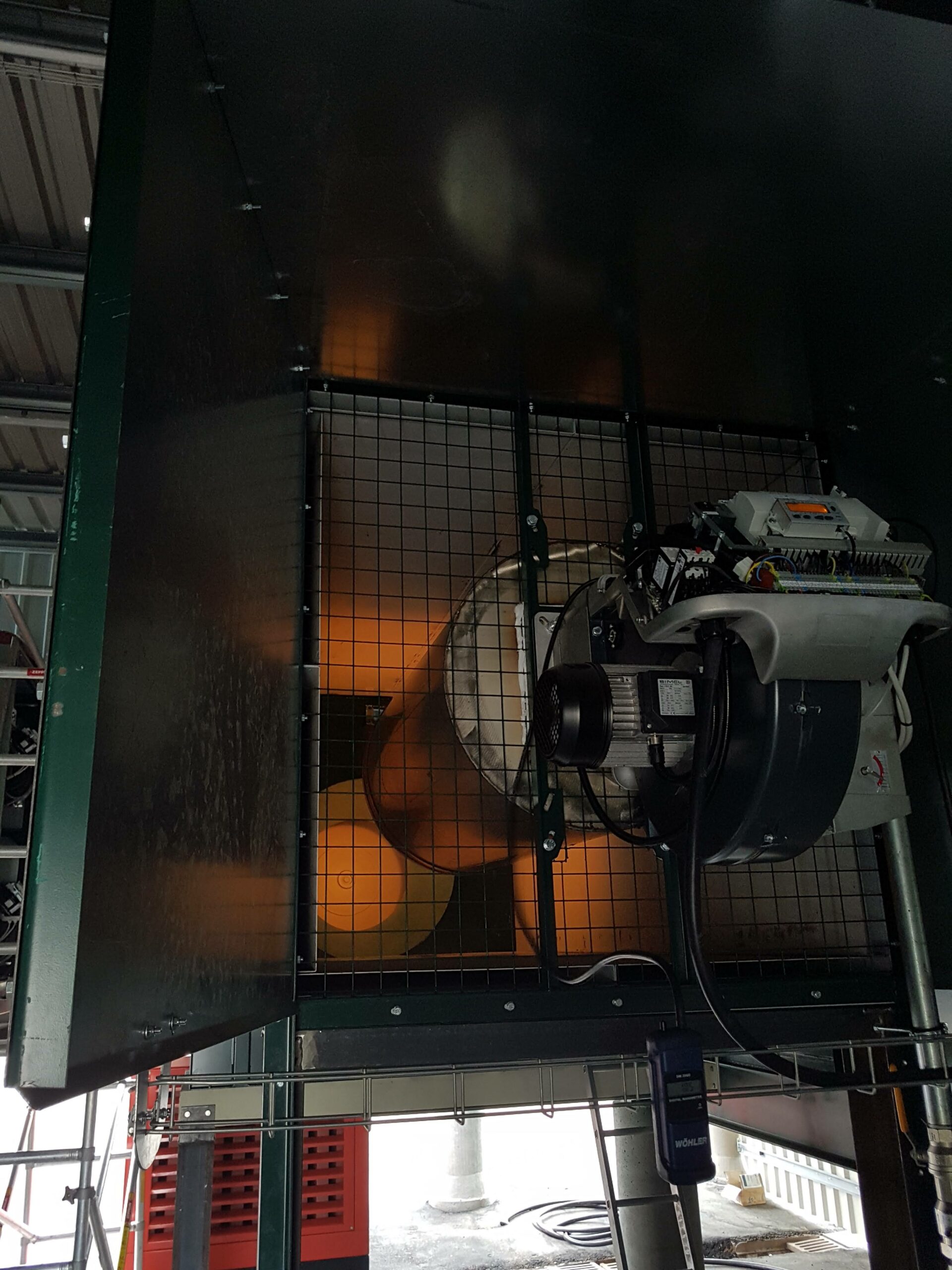

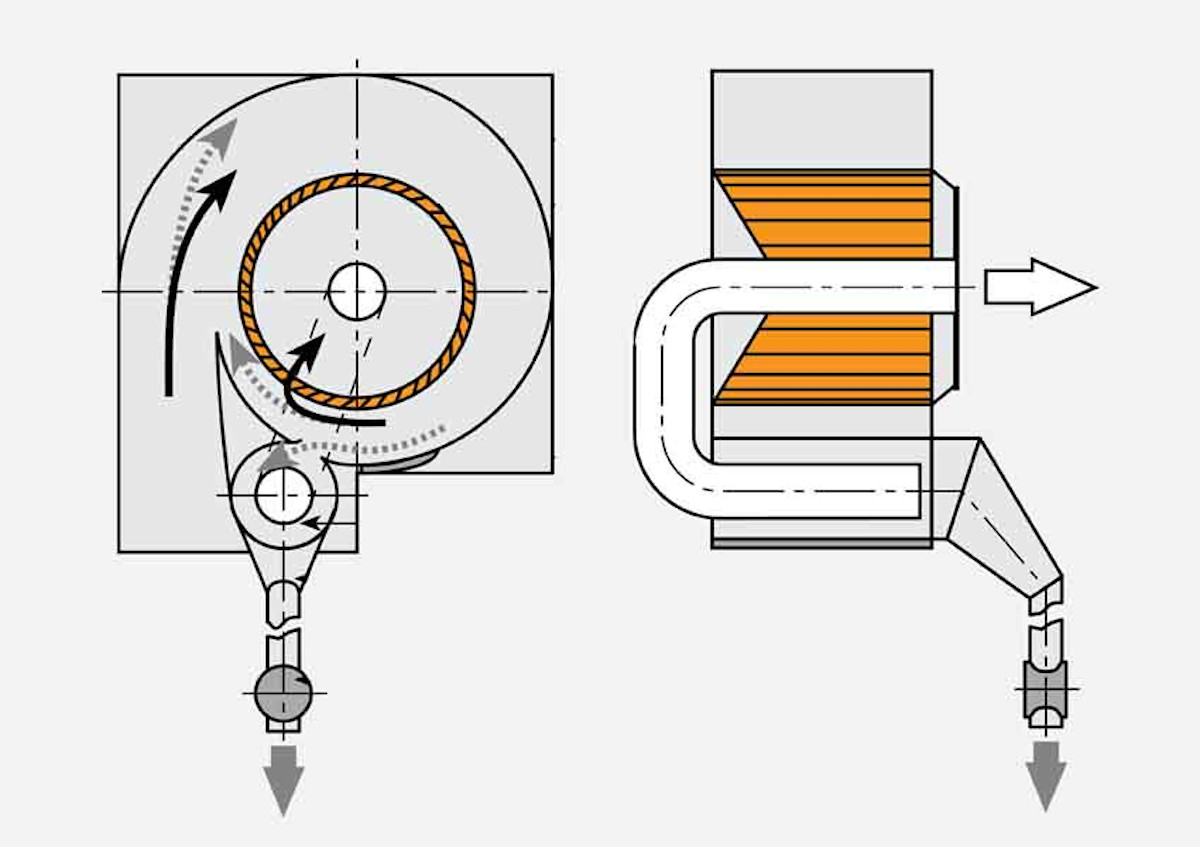

Silent and clean drying technology

Our continuous flat bed dryer cannot be compared with a conveyor belt dryer. The product to be dried is gently guided over the drying bed by the circulating conveyor chain. Variable air volumes through the use of frequency converters – therefore also low noise level. Each dryer is divided into several sections – for each specific product the temperature and air flow in these sections can be adjusted. Energy efficiency can be increased by heat recovery. Low emission values for dust through targeted air flow adjustment.

Advantages:

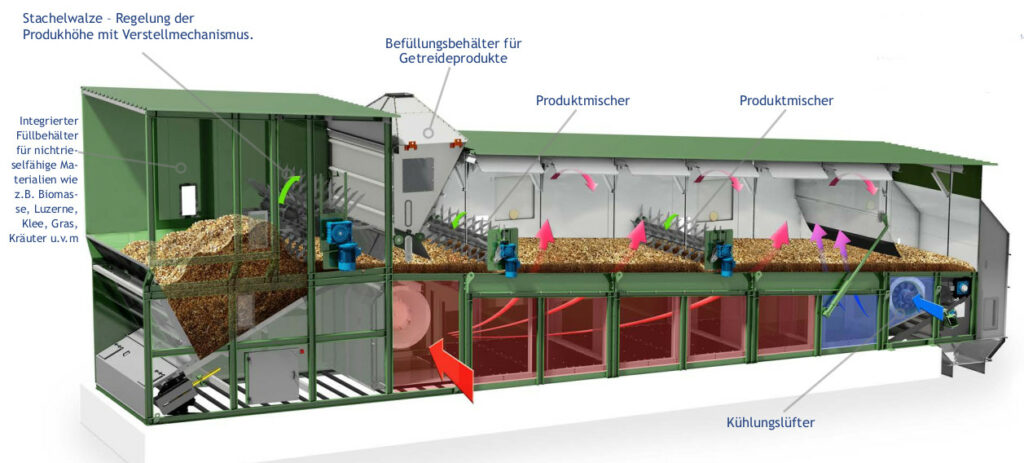

Pre-bunker for non-free-flowing materials

Separate inlet area for grain (free-flowing materials)

Gentle product mixer in the drying bed

Clean, easy cleaning

Low noise level

Vorteile:

Vorbunker für nicht-rieselfähige Materialen

Eigener Einlaufbereich für Getreide (rieselfähige Materialien)

Schonende Produktmischer im Trocknungsbett

Saubere, einfache Reinigung

Niedriger Geräuschpegel

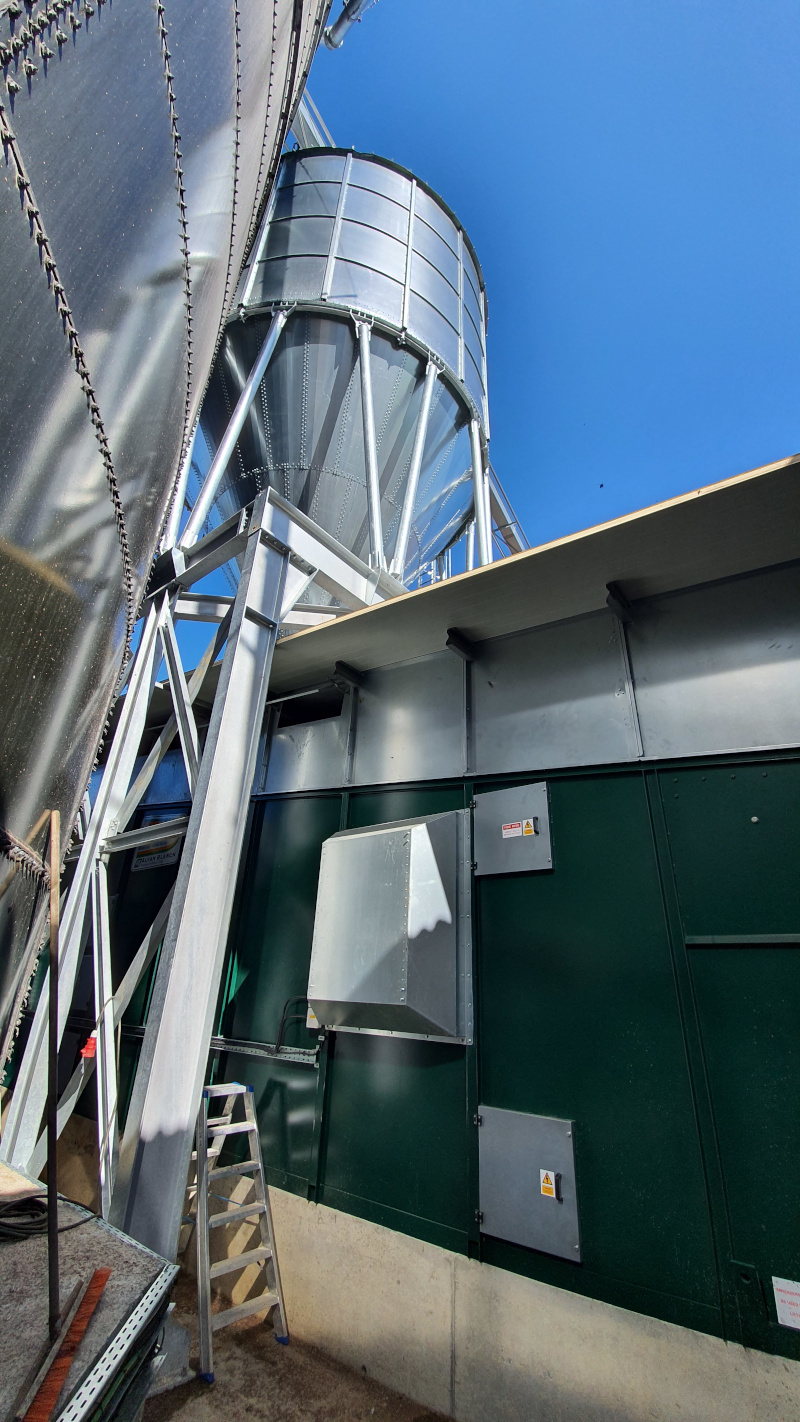

At these locations you will find an Alvan Blanch dryer: